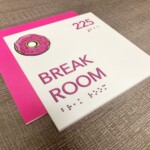

UV Flatbed Printed ADA Signs

UV Flatbed Printed ADA Signs (aka 3D printed) are made by using UV Flat Bed Printers to print tactile copy and braille using multiple passes to build the ink up to a height of 1/32” from the background. These are not actually 3D printed although some architects and designers use that term when specifying this construction.

Identification: Tactile copy will have a slightly rounded appearance and the color of the surface and side of the tactile copy will be the same

Production: We start by applying a special coating to the substrate (usually acrylic or ACM) to assist the adherence of the ink. We print tactile copy, pictograms and braille using our state-of-the-art Canon Arizona UV Flatbed printers. Signs then get a matte clear coat which provides both UV protection and protection from generally used cleaning materials.

Advantages: UV Flatbed Printed ADA Signs can be produced faster than most other manufacturing techniques. They are comparable in durability with Acrylic with Applique ADA Signs. We do not recommend using this type of fabrication outdoors.

Disadvantages: We do not recommend using this type of fabrication outdoors.

Add-ons: UHB Tape for Mounting, Holes Drilled/Countersunk for Mounting, Radius Corners, Beveled Edges, Accent Bars, Back Plates, Cubicle Hangers, Window Areas for Paper Inserts, Conference Sliders, Wood Laminates, Metal Laminates, Inserted in Frames, and many more!